Technical Information & Available Models

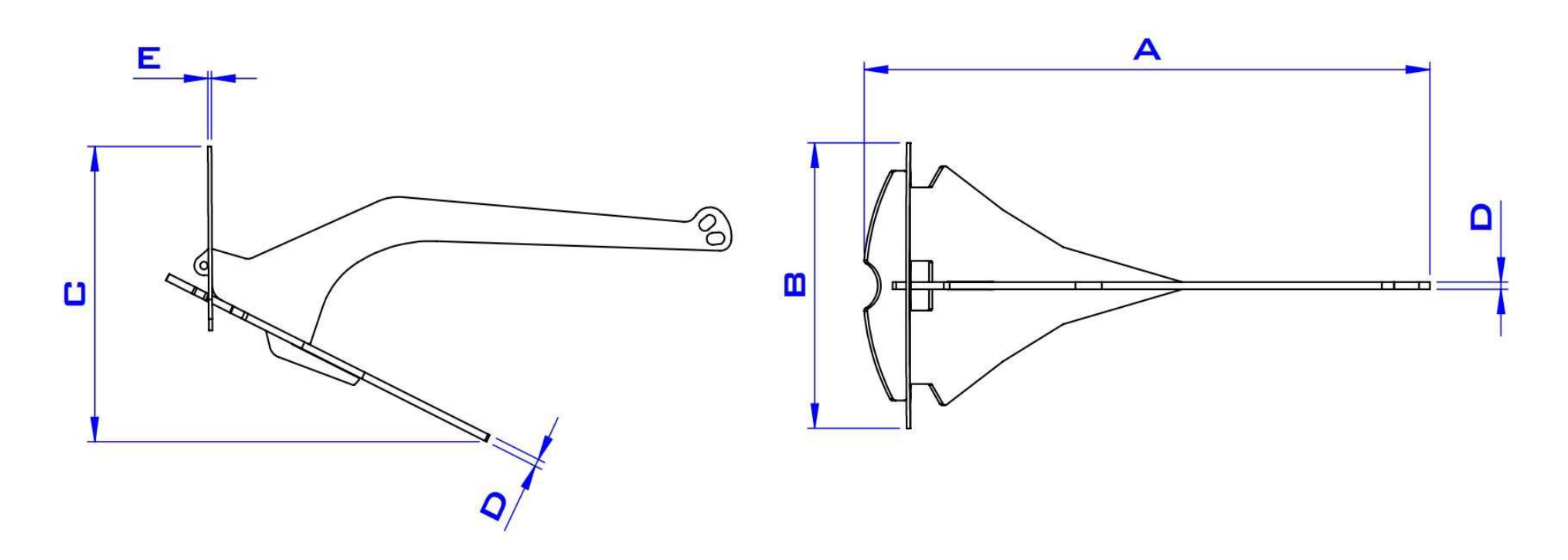

Technical details of the ANKERPLEX® anchor

ANKERPLEX® consists of three quality normalized flat sheet metal parts designed in such a way that with a simple connection between them, and their securing with a simple shackle arranged at the end, the assembly quickly becomes a solid and self-supporting three-dimensional unit, load-bearing, totally effective in terms of positioning, speed of penetration into the seabed, holding power, and resetting in changes of trajectory.

ANKERPLEX® has no moving parts which avoids any possibility of blockage during use or damage when handling it.

This feature (cut flat sheet metal) facilitates its production, storage and transport, while allowing easy stowage as a kedge or spare anchor, and with the advantage of particularly quick assembly for use without the possibility of errors, without tools and without this implying a detriment to its resistance and operational capacity. (See instructions for use section).

Technical features

SELF–LAUNCHING: The shapes and weight distribution of the Ankerplex anchor allow its free fall from the bow roller, without intervention, simply by releasing the chain from the windlass.

Manufacturing is carried out from standard sheets, by means of high-precision robotic cutting and simple surface finishing made by mechanical means. In the manufacture of the Ankerplex anchor, no welding or folding process is involved, which guarantees that its characteristics remain unchanged for life.

Ankerplex is manufactured and marketed in different sizes to meet needs of all types of vessels: from small boats, jetskys and kayaks to sailboats and yachts over twenty tons.

Ankerplex is supplied in STAINLESS STEEL, ALUMINIUM and HOT-DIP GALVANIZED STEEL versions to cover your specific needs:

- AISI 304 STAINLESS STEEL models, through electropolishing treatment, easily meet the requirements of resistance required in saline environments while obtaining an impeccable and very durable gloss finish.

- The ALUMINIUM models are manufactured using Al-Mg MARINE GRADE PLATE AL5083 and AL5754 to obtain adequate mechanical resistance, lightness and durability with anodized finish, ideal for use as auxiliary anchors for occasional or intermittent use, as gear for racing boats, seaplanes,…or any use where the low weight is an added value.

- The HOT-DIP GALVANIZED STEEL option is offered as a low-cost, robust unit with good corrosion protection, ideal as a main anchor, kedge, or replacement spare anchor.

- On-demand, Ankerplex can be made in other materials, such as bronze sheet, brass, nylon, etc. and it is scalable to large formats for industrial uses, aquaculture, prospecting, oil rigs, etc. Ask us about your specific needs.

Ankerplex’s manufacturing processes are carried out with the most advanced technology using high-precision robotic systems, and all Ankerplex production and its quality are examined and controlled unit by unit by expert staff.

CHOOSE THE RIGHT MODEL FOR YOUR BOAT

Know more

Note that this guide is a proposal based on the manufacturer’s experience, specialized publications, and field tests. It is not a formal statement of the model required for each boat. There may be regulations and standards in different countries, requirements of classification bodies or insurance companies, which condition the weight and characteristics of the anchor of your boat, and that you must know and attend to.

Product sheet

Scheme dimensions and models